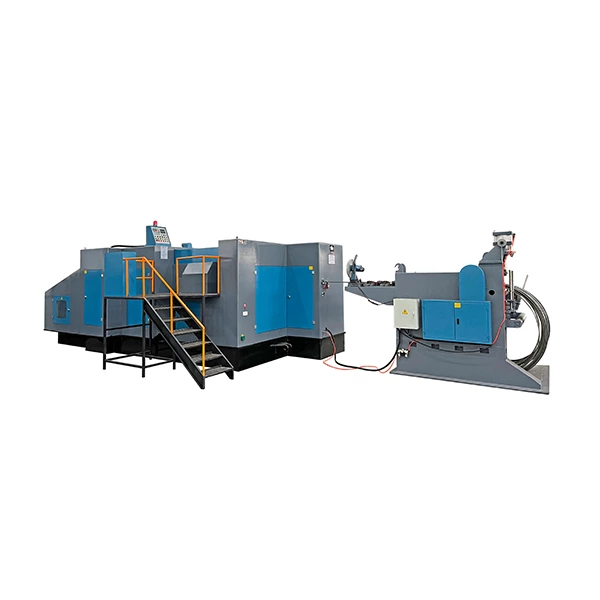

The six die six blow cold heading machines are greatly enhanced in every aspect.This series is designed specifi-cally in the production of auto & motorcycle parts,irregualr parts, broaching non-standard parts.

This machine part adopts strict casting process to eliminate residual stress, so as to prevent deformation during use and maintain high accuracy of machine parts for a long time

The processing and forming of metal parts in cold heading machines originally required multiple mechanical processes for cutting. However, usIng cold heading canminimize or eliminate cutting, and directly shape them intothe desired shape and size. This not only saves a lot of materials,but also significantly improves production efficiency and mechanical strength.

The the third mock examination three punch multi station cold heading machine uses cold dial elements or bar shaped materials, which become light hexagonal nuts after tapping.The cold heading machine is horizontal and the worksta-tions are arranged horizontally. The entire process offeeding, cutting, clamping, and cold heading is automatic.